Rivets cut the head into an X and than chisel the head off. Than punch it through frame. How I've always done them and I use my air hammer once head is cut and some I don't even have to cut because big Mac air hammer with good chisel in it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1985 k10 prerunner ideas?

- Thread starter 6.2slowboi

- Start date

6.2slowboi

New member

- Joined

- May 18, 2023

- Messages

- 19

my cold chisel is going to get alot of work in it seems XD

6.2slowboi

New member

- Joined

- May 18, 2023

- Messages

- 19

with like an angle grinder?If you cut an X in the head the chisel doesn't take much work to get it smooth

the bodj

Well-known member

Screw a hand chisel. Use a cheap air hammer. Sharpen the tip of the air hammer chisel with a disc sander or whatever you have, cut an x in the head like Tommy said, and then knock the head off with the air hammer. I can get one off in under 45 seconds. A sharp chisel is key, though.

6.2slowboi

New member

- Joined

- May 18, 2023

- Messages

- 19

yeah the only shitty thing is i dont have an air compressor XD my buddy might, right now im just hunting for springs before i get all that stuff, im talking to a trans shop to get my trans gone through... didnt realize it was so expensiveScrew a hand chisel. Use a cheap air hammer. Sharpen the tip of the air hammer chisel with a disc sander or whatever you have, cut an x in the head like Tommy said, and then knock the head off with the air hammer. I can get one off in under 45 seconds. A sharp chisel is key, though.

gtrainor21

Active member

Lots of good info floating around on this one! But these guys all make great points... Build as you drive and building according to use.

I've got a K5 that I've put together thats leafs all the way around that works decent. I used a lot of ORD parts on it and all have been great products. ORD springs are manufactured by Alcan in Grand Junction to their specs. I have yet to have any issues with my ORD springs. Its no go fast machine by any means but it'll do just about anything I throw it at.

I don't want to get repetitive on what's already been covered but I do want to touch on a couple points that have been mentioned already.

-crossover steering: do it now, I have yet to do mine and I hate every second I drive it for that reason

-leave the tension shackles in rear: I kept the tension shackles in the rear of my K5 and it works great (of course with a longer shackle). Stock length ORD custom leafs in the rear with their longer HD shackles will give you at least 12" of rear travel, I bet you could squeeze 14-16" under a pickup though since I only have so much room for shocks under my K5 so keep that in mind.

So one issue I'm running into with my K5 is uptravel in the front, so I don't think going undersprung in the front will win you any benefits. a longer leaf spring will still be a huge improvement though.

Here's my .02 with what I would do with a limited budget and a set of 52" springs on hand. This should get it back in the dirt sooner than later and make the truck pretty capable plus help you focus funds on infrastructure that can be used for future upgrades and safety related items.

front:

get the brackets to convert the front to 52" springs, move the rear springs to the front and pull the overload out (the big ugly thick leaf at the bottom). crossover steering. find a set of 2.5 smooth body shocks (longest you can fit) and run it like that until money permits the next better thing up front whether its TTB, Links, whatever. Run limit straps, they're cheap insurance. save up and add bump stops when you can.

Rear:

slap a set of ORD rear leafs in with some 6" ORD shackles that will match the lift on the front (will likely be around 3-4 inches). again, a set of smooth body 16 x 2.5" shocks and get ready to cut holes in the bed. might as well bed cage the thing now. Of course cycle your springs, install your limit straps, install some bumps when the funds permit. But from there drive it, play with the valving, and find its limits and that way you know what direction you want to take the truck when you have the money.

I've got a K5 that I've put together thats leafs all the way around that works decent. I used a lot of ORD parts on it and all have been great products. ORD springs are manufactured by Alcan in Grand Junction to their specs. I have yet to have any issues with my ORD springs. Its no go fast machine by any means but it'll do just about anything I throw it at.

I don't want to get repetitive on what's already been covered but I do want to touch on a couple points that have been mentioned already.

-crossover steering: do it now, I have yet to do mine and I hate every second I drive it for that reason

-leave the tension shackles in rear: I kept the tension shackles in the rear of my K5 and it works great (of course with a longer shackle). Stock length ORD custom leafs in the rear with their longer HD shackles will give you at least 12" of rear travel, I bet you could squeeze 14-16" under a pickup though since I only have so much room for shocks under my K5 so keep that in mind.

So one issue I'm running into with my K5 is uptravel in the front, so I don't think going undersprung in the front will win you any benefits. a longer leaf spring will still be a huge improvement though.

Here's my .02 with what I would do with a limited budget and a set of 52" springs on hand. This should get it back in the dirt sooner than later and make the truck pretty capable plus help you focus funds on infrastructure that can be used for future upgrades and safety related items.

front:

get the brackets to convert the front to 52" springs, move the rear springs to the front and pull the overload out (the big ugly thick leaf at the bottom). crossover steering. find a set of 2.5 smooth body shocks (longest you can fit) and run it like that until money permits the next better thing up front whether its TTB, Links, whatever. Run limit straps, they're cheap insurance. save up and add bump stops when you can.

Rear:

slap a set of ORD rear leafs in with some 6" ORD shackles that will match the lift on the front (will likely be around 3-4 inches). again, a set of smooth body 16 x 2.5" shocks and get ready to cut holes in the bed. might as well bed cage the thing now. Of course cycle your springs, install your limit straps, install some bumps when the funds permit. But from there drive it, play with the valving, and find its limits and that way you know what direction you want to take the truck when you have the money.

6.2slowboi

New member

- Joined

- May 18, 2023

- Messages

- 19

This has been a wealth of information and I couldn't be happier with the support, this is definitely a long term sort of situation, but It's always been about the long haul. Right now I'm watching to see what will happen next, being so young money is tight and with all the economy stuff going on right now there's a lot of variables I'm taking into consideration. I had a line on some 52" springs, but the guy ran out on me, live and learn. I think, at least, for this season I'll run the truck how it is and finish up my gauges and dash before I really hit the big money things. Not to mention I only have 31s on the truck better run those till they are bald before going up to a 33.Lots of good info floating around on this one! But these guys all make great points... Build as you drive and building according to use.

I've got a K5 that I've put together thats leafs all the way around that works decent. I used a lot of ORD parts on it and all have been great products. ORD springs are manufactured by Alcan in Grand Junction to their specs. I have yet to have any issues with my ORD springs. Its no go fast machine by any means but it'll do just about anything I throw it at.

I don't want to get repetitive on what's already been covered but I do want to touch on a couple points that have been mentioned already.

-crossover steering: do it now, I have yet to do mine and I hate every second I drive it for that reason

-leave the tension shackles in rear: I kept the tension shackles in the rear of my K5 and it works great (of course with a longer shackle). Stock length ORD custom leafs in the rear with their longer HD shackles will give you at least 12" of rear travel, I bet you could squeeze 14-16" under a pickup though since I only have so much room for shocks under my K5 so keep that in mind.

So one issue I'm running into with my K5 is uptravel in the front, so I don't think going undersprung in the front will win you any benefits. a longer leaf spring will still be a huge improvement though.

Here's my .02 with what I would do with a limited budget and a set of 52" springs on hand. This should get it back in the dirt sooner than later and make the truck pretty capable plus help you focus funds on infrastructure that can be used for future upgrades and safety related items.

front:

get the brackets to convert the front to 52" springs, move the rear springs to the front and pull the overload out (the big ugly thick leaf at the bottom). crossover steering. find a set of 2.5 smooth body shocks (longest you can fit) and run it like that until money permits the next better thing up front whether its TTB, Links, whatever. Run limit straps, they're cheap insurance. save up and add bump stops when you can.

Rear:

slap a set of ORD rear leafs in with some 6" ORD shackles that will match the lift on the front (will likely be around 3-4 inches). again, a set of smooth body 16 x 2.5" shocks and get ready to cut holes in the bed. might as well bed cage the thing now. Of course cycle your springs, install your limit straps, install some bumps when the funds permit. But from there drive it, play with the valving, and find its limits and that way you know what direction you want to take the truck when you have the money.

drewwithpants

New member

- Joined

- Jan 20, 2023

- Messages

- 3

Ahh I remember those days when I first bought my k20 pickup trying to figure all this stuff out. My truck started off as more of a wheeler/rock crawler In one of the early iterations of the suspension on my truck I just made some bastard spring packs out of stock junk yard packs. 52 inch front springs front the rear of a blazer and 1/2 ton 63s out of a newer Silverado is what I picked up from pick apart. Moved the stock hangars forward and utilized a 5.5" long shackle in the front. Found some super cheap 2.5x14 FOAs for the front and some rear super duty dirt logic 2.0 takeoffs for the rear. Keep in mind any front leaf spring setup (crossover & push pull) will have a TON of bump steer if you actually start getting any real travel out of it. Not the best for dippin in the dez

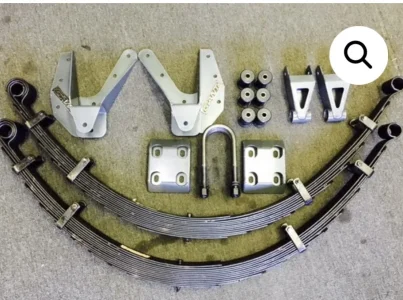

Everyones gotta start somewhere. Check out Roberts Custom Trucks! We are here in Montclair CA and we build custom coilover and leaf spring kits for mostly older chevy trucks. We have a multitude of products that could even just spark some ideas.

Everyones gotta start somewhere. Check out Roberts Custom Trucks! We are here in Montclair CA and we build custom coilover and leaf spring kits for mostly older chevy trucks. We have a multitude of products that could even just spark some ideas.

Yeah depending on how much travel you want or expect out of the front to help with bumpsteer would be to do crossover steering and add a track bar. It's only gonna allow so much limited travel since track bar swing is an arc like steering, to help with bumpsteer, but it pulls axle side to side which fights the leaf spring motion which is vertically. I would look into other solid front axle trucks for ideas on how they work/perform to add those to the K10 pickup to help with it.

Know what this is??? K10 frame im fixing

Had this truck for over 20 years

Did all the stupid stuff everyone told me to not do and learned from it

Drived danm good even with the carb issues

On front i have skyjacker soft ride leafs, used them with 4tube bypass, replaced the shackle mount with the ORD mount

Rear has hybrid leafs and custom rear hangers, leafs are from a tundra dont recall the leaf id but i kept my stock main because i didnt want to move the hanger and slapped the tundra leafs to it, ride is firm but once you hit dirt its awesome with the 2 tube bypass i run

That route will take you to driveshaft angles, have to go over that, stock slip in yoke wont cut it for long travel

Steering like said already crossover steering and remove the sway bar, got my kit from sly manufacturing a while back when stuff was cheap

Pressed some thicker lug studs on all 4 corners, chromoly axle shafts

And cage is up to you, i cut mine to re do it

Had this truck for over 20 years

Did all the stupid stuff everyone told me to not do and learned from it

Drived danm good even with the carb issues

On front i have skyjacker soft ride leafs, used them with 4tube bypass, replaced the shackle mount with the ORD mount

Rear has hybrid leafs and custom rear hangers, leafs are from a tundra dont recall the leaf id but i kept my stock main because i didnt want to move the hanger and slapped the tundra leafs to it, ride is firm but once you hit dirt its awesome with the 2 tube bypass i run

That route will take you to driveshaft angles, have to go over that, stock slip in yoke wont cut it for long travel

Steering like said already crossover steering and remove the sway bar, got my kit from sly manufacturing a while back when stuff was cheap

Pressed some thicker lug studs on all 4 corners, chromoly axle shafts

And cage is up to you, i cut mine to re do it

JakewithKhakis

New member

I have an 86 K10 shortbed with a mild prerunner build. Linked up front with 14" coilovers and customs springs out back with bypasses. It worked pretty dang good. Had great street manners too. I've built a few trucks with similar setups. Some with bigger shock packages and longer travel but the basic 2.5x14 boogies for a solid axle trucl. I'm currently working on a TTB setup for my K5 since I do want to go fast.

Attachments

Staying on leafs can be done fairly cheaply. You are on the right track. I copied my buddy Adam, he runs ford 57’s from a 95ish f150. I think I got em shipped for 190 from sd truck springs. You can pull 13” of wheel travel with a shackle flip. Anything more than that and the springs start to go way negative arch. Adam runs gen 1 raptor shocks and they work well. He has ord custom springs in the front. Me I 3 linked the front ofmine, but will be going ttb soon. Staying leaf in the rear gives the truck stability.

Attachments

Giant Geoff

Well-known member

I have done a couple ttb conversations and it suck ass to do, so difacult! It is even harder on your truck because your frame is narrow and the 3rd member will hit the drive side frame horn plus you’ll have to switch out the T-case to a driver drop. I’ve been a hard core I-beam most of my life and would not do it if I were you. I have my 1st straight axle pre-runner right now and love it! Just turn what you have and I have a Spring under rear kit for your truck that fells like a link.

Attachments

the bodj

Well-known member

Man I freaking love k5s! I’ll definitely build myself one someday

gtrainor21

Active member

I would've never thought about the 3rd member having clearance issues on the frame rail with TTB. How much concern is driveline angle with the older GM axles? seems to me it would be worth it to just go driver drop on the T-Case anyway and use a HP D60. I know I'm kind of pushing the limits of the front CV on my K5 at full droop, and that's with leaf springs and maybe 12" up front...I have done a couple ttb conversations and it suck ass to do, so difacult! It is even harder on your truck because your frame is narrow and the 3rd member will hit the drive side frame horn plus you’ll have to switch out the T-case to a driver drop. I’ve been a hard core I-beam most of my life and would not do it if I were you. I have my 1st straight axle pre-runner right now and love it! Just turn what you have and I have a Spring under rear kit for your truck that fells like a link.

Similar threads

- Replies

- 80

- Views

- 3K