Endless Trails

Well-known member

- Joined

- Apr 7, 2022

- Messages

- 594

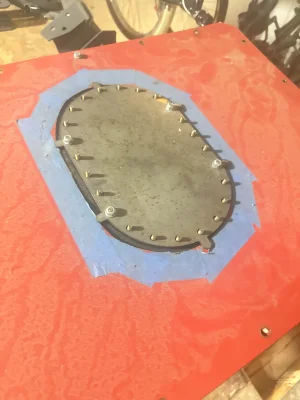

I want to hear the theory better as well to see how close I am to guessing the engineering.definetely a stupid question, even for me, but............. i dont understand this whole setup. is it just to eliminate axle wrap? i can see if you did one setup over the other for axle wrap, but both seem redundant? (think thats the right smart word.... but im medically ratarded soooooooooo......... haha)

wouldnt just the upper "link"/pannhard bar (i think thats what it is?) do the same thing as the chingadearas coming off the lower spring plate/perch, to the front of the axle??

please explain it to a 6.9 year old, Geoff!

My take is that separating the axle from the springs might free up the movement of the springs. The upper bars will control the axle wrap by themselves, but wouldn't allow pinion adjustment. The spring from the front mount to the spring pad will lengthen as it flattens (compresses). If that is getting longer and the anti wrap bars (upper lengths) is fixed length then the two fight. This design could also keep the pinion angle where you want it through the travel.

The panhard just controls the horizontal movement. Typically the having the axle clamped hard to both springs and the front spring bushings being fairly tight in the front mounts great a box that controls the side to side.

How close am I because I am mostly guessing?