I know, FOAs are frowned upon, but I just wanted to know why, they seem like a good deal.

So here is my little straight out of the box tune up session I did on a pair that I am planing to run on a truck.

They came black powdercoated, which is nice.

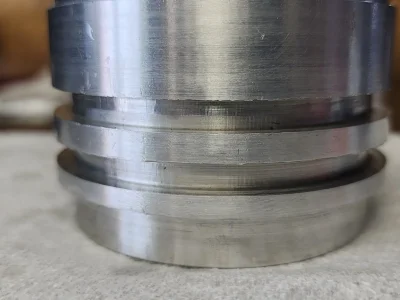

The seal head and piston, look at the burrs and chatter:

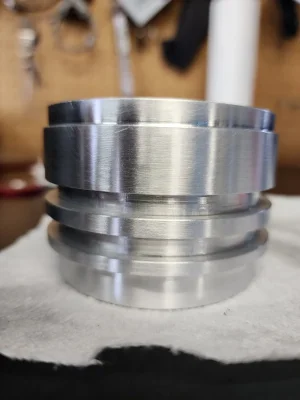

Deburred, was that so hard?

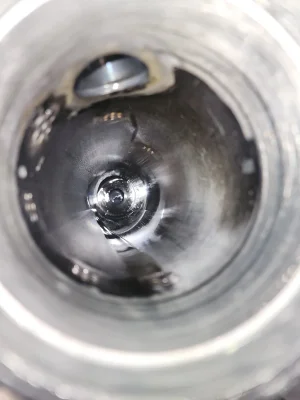

Then the Valve stack. Whatttttt? (Piston Deburred in this picture) how can the shims be rusty when they live in oil? They are very bad shims.

New raptor leaf valve tune stack in:

Mostly king or sdi shims

Hose upgrade for that rebound assist with the leafs:

The upper eye is about 1/2" lower than most brand shocks, so you may need to modify any standard mounting, but it also makes the shock shorter.

The bearings are also quite loose, I went ahead and made some bumpers for mine until I upgrade them.

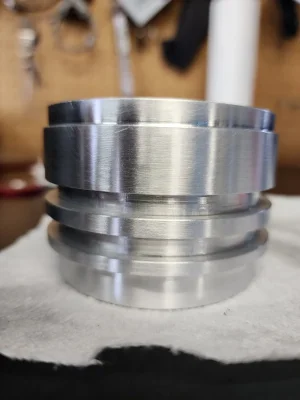

Side by side

Next up: run them and see what happens I plan to add a bleeder to the IFP next time I have them apart.

Okidoke now you know!

So here is my little straight out of the box tune up session I did on a pair that I am planing to run on a truck.

They came black powdercoated, which is nice.

The seal head and piston, look at the burrs and chatter:

Deburred, was that so hard?

Then the Valve stack. Whatttttt? (Piston Deburred in this picture) how can the shims be rusty when they live in oil? They are very bad shims.

New raptor leaf valve tune stack in:

Mostly king or sdi shims

Hose upgrade for that rebound assist with the leafs:

The upper eye is about 1/2" lower than most brand shocks, so you may need to modify any standard mounting, but it also makes the shock shorter.

The bearings are also quite loose, I went ahead and made some bumpers for mine until I upgrade them.

Side by side

Next up: run them and see what happens I plan to add a bleeder to the IFP next time I have them apart.

Okidoke now you know!

Attachments

Last edited: