You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Print Chat

- Thread starter badlinesgoodtimes

- Start date

gascapkevin

Well-known member

- Joined

- May 9, 2023

- Messages

- 174

https://www.youtube.com/watch?v=pSYseI2gioA

Just watched this video and found it pretty interesting.

Just watched this video and found it pretty interesting.

BajaKyle

Active member

- Joined

- May 21, 2022

- Messages

- 90

Bumping an old thread, long story short my son (7 years old) has taken a huge interest in 3D printing and seems to really excel in STEM activities, he wants a printer now and I'm pretty ok with it. That being said I have pretty much narrowed it down to a Bambu P1S with the AMS attachment, rationalizing the cost and getting this unit because it's definitely an activity we can do together and it seems this printer has good reviews and we probably won't outgrow it....so, the normal stuff he can download and print for free seems cool (fidgets, toys, etc) but I would like to learn how him n I can design our own stuff...I found program called "Blender" that seems to be pretty straightforward but what is everyone using or what would you guys recommend for a new guy just trying to break into this 3d print world?

Fenix Motorsports

Active member

I tried blender when I first started CAD/3D Printing, I hated it so much, eventually I got turned on to Fusion (still using). Blender is better for building and modifying mesh layouts, where fusion is more "engineering focused" I guess you could say? Its a full design to production suite basically, instead of being focused on video game models and animation like blender. Both are free, I'd try both and see which you prefer, I personally just could never get into blender.Bumping an old thread, long story short my son (7 years old) has taken a huge interest in 3D printing and seems to really excel in STEM activities, he wants a printer now and I'm pretty ok with it. That being said I have pretty much narrowed it down to a Bambu P1S with the AMS attachment, rationalizing the cost and getting this unit because it's definitely an activity we can do together and it seems this printer has good reviews and we probably won't outgrow it....so, the normal stuff he can download and print for free seems cool (fidgets, toys, etc) but I would like to learn how him n I can design our own stuff...I found program called "Blender" that seems to be pretty straightforward but what is everyone using or what would you guys recommend for a new guy just trying to break into this 3d print world?

BajaKyle

Active member

- Joined

- May 21, 2022

- Messages

- 90

I haven't played with anything yet so I will definitely look into that thank you.I tried blender when I first started CAD/3D Printing, I hated it so much, eventually I got turned on to Fusion (still using). Blender is better for building and modifying mesh layouts, where fusion is more "engineering focused" I guess you could say? Its a full design to production suite basically, instead of being focused on video game models and animation like blender. Both are free, I'd try both and see which you prefer, I personally just could never get into blender.

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

Learning a parametric based CAD program would be my recommendation to set up building functional models instead of artsy models from Blender. Solidworks is a great example but definitely not free. Freecad, Onshape, and Sketchup are commonly used free programs that have plenty of online tutorials. Once you understand the workflow of drawing a sketch and either building from it or using it to subtract than you add more difficult functions. My middle son was 9 when he learned the basics on Solidworks and probably could've started earlier if the interest was there.

the bodj

Well-known member

You can get "solidworks for makers" for I think $25/year. It's a heck of a deal. I find the free/low cost solidworks/fusion are best for non-organic shapes, while others (blender) are better for figurines and curvy shapes.

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

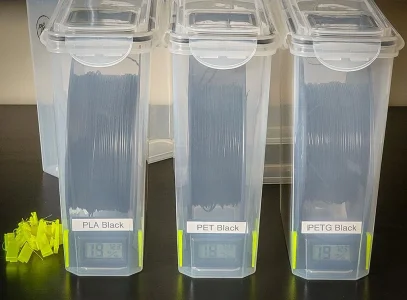

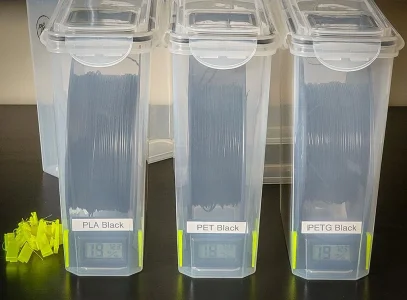

Bodj recently asked about printing PETG and I have struggled bigly for quite awhile before finally figuring it out. The biggest issue is that it sucks all the moisture from the air and makes it stringy and globby enough to ruin your print.

My basic approach for printing:

-Build box around the printer with door to keep heat even. My box is wood to stabilize humidity further

-Place the filament in the heated environment. The extruder does a decent job lowering humidity in a closed space, I've seen 15% inside when 35-40% ambient humidity. I have holes drilled in the top of my wooden enclosure and a trash can covering the reel, pretty basic but works.

-Store filament in a plastic cereal box with dessicant beads to keep dry. This actually dries the filament albeit super slow. Mine read 10% humidity after a couple hours and have stayed there as long as it's been closed.

-PETG specific, reduce bed temp to 40C after first layer to help with elephant footing and base warping.

https://www.amazon.com/DWËLLZA-KITC...917667&sprefix=cereal+bo,aps,163&sr=8-43&th=1

https://www.amazon.com/Desiccant-In...prefix=blue+desicant+bag,aps,163&sr=8-11&th=1

https://www.amazon.com/Hygrometer-H...918546&sprefix=humidity+sensor,aps,197&sr=8-6

My basic approach for printing:

-Build box around the printer with door to keep heat even. My box is wood to stabilize humidity further

-Place the filament in the heated environment. The extruder does a decent job lowering humidity in a closed space, I've seen 15% inside when 35-40% ambient humidity. I have holes drilled in the top of my wooden enclosure and a trash can covering the reel, pretty basic but works.

-Store filament in a plastic cereal box with dessicant beads to keep dry. This actually dries the filament albeit super slow. Mine read 10% humidity after a couple hours and have stayed there as long as it's been closed.

-PETG specific, reduce bed temp to 40C after first layer to help with elephant footing and base warping.

https://www.amazon.com/DWËLLZA-KITC...917667&sprefix=cereal+bo,aps,163&sr=8-43&th=1

https://www.amazon.com/Desiccant-In...prefix=blue+desicant+bag,aps,163&sr=8-11&th=1

https://www.amazon.com/Hygrometer-H...918546&sprefix=humidity+sensor,aps,197&sr=8-6

the bodj

Well-known member

That's good info. I'll have to revisit it when I try printing PETG again. I've got ABS down pretty good now, but PETG would be nice for food grade stuff or things that need to be more flexible.

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

I tried printing ABS for the first time last weekend and it failed miserably. It was also old filament that had been sitting out for years and I had no time to try to fix the gross warping there was. It even shrunk so much it cracked between layers.

I've never heard of PETG being more flexible, I know the single wall supports are more brittle and crack apart unlike PLA or the ABS I failed at. It is stronger than PLA when loaded in layer from experience with little RC A-arms.

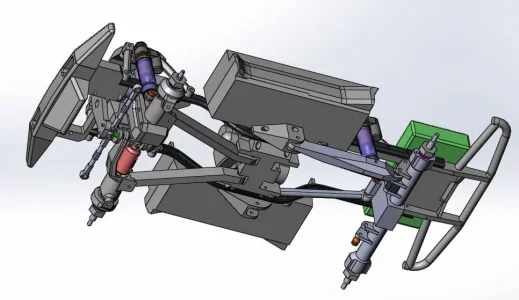

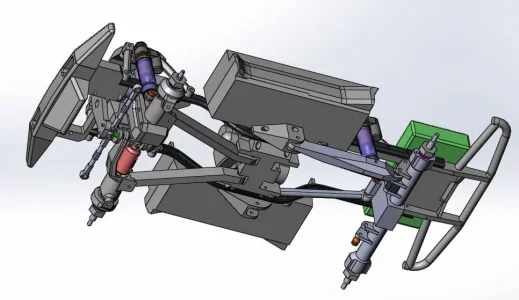

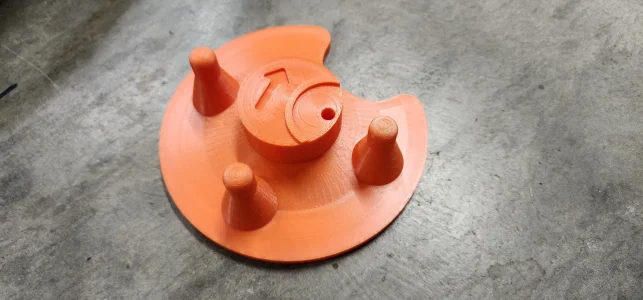

Shameless plug while this thread is bumped, I released an IFS design for the SCX24 that I've been tinkering with for a few years now. Clearly not a resounding commercial success, lol.

https://cults3d.com/en/3d-model/game/scx24-independent-front-suspension-4wd-ifs-kit

I've never heard of PETG being more flexible, I know the single wall supports are more brittle and crack apart unlike PLA or the ABS I failed at. It is stronger than PLA when loaded in layer from experience with little RC A-arms.

Shameless plug while this thread is bumped, I released an IFS design for the SCX24 that I've been tinkering with for a few years now. Clearly not a resounding commercial success, lol.

https://cults3d.com/en/3d-model/game/scx24-independent-front-suspension-4wd-ifs-kit

the bodj

Well-known member

I'll have to look at my print/bed temps, but I found the key is no fan running at all. My machine has a built in enclosure, so I keep it closed at all times, fan off, and that's about it. I've found it to print pretty effortlessly, to be honest.

I used that same container to hold my open filaments!Bodj recently asked about printing PETG and I have struggled bigly for quite awhile before finally figuring it out. The biggest issue is that it sucks all the moisture from the air and makes it stringy and globby enough to ruin your print.

My basic approach for printing:

-Build box around the printer with door to keep heat even. My box is wood to stabilize humidity further

-Place the filament in the heated environment. The extruder does a decent job lowering humidity in a closed space, I've seen 15% inside when 35-40% ambient humidity. I have holes drilled in the top of my wooden enclosure and a trash can covering the reel, pretty basic but works.

-Store filament in a plastic cereal box with dessicant beads to keep dry. This actually dries the filament albeit super slow. Mine read 10% humidity after a couple hours and have stayed there as long as it's been closed.

-PETG specific, reduce bed temp to 40C after first layer to help with elephant footing and base warping.

https://www.amazon.com/DWËLLZA-KITCHEN-Cereal-Containers-Storage/dp/B0FFHM5LKC/ref=sr_1_43?crid=32WLPIIKCK8X5&dib=eyJ2IjoiMSJ9.aabHQMRxeK7wU50w6DiMDPsaEtDy1H1NRF9rgJR57iDcsTUIvW5Hjlj_w8JeNDcnRCffcmDA2ZczHOiAor7q1xSNLBFblPI4dANaDhiOgv7cfIrptfM1rsebJec_xCcyBUORzL-4q9ubSpPxUaiYwBpxsrdIkX5TI1pNqF4g9dqN04-GE4D3t9DkHffsdx3OwKYNIGkZI4RicunnRnelzH7y5sZ4Vjg1CaAuox1bUnRWbopFYC_i7_7Jh_3RgScfbJpYlDH2XDCuEm7m9Szn3ZzKjpEPZN5IO0HIcbG5UqI.Jc0_frUSqNPQ8rv75Z4jp5DFOjbZWyJOobBVTf6uz7U&dib_tag=se&keywords=cereal+box&qid=1756917667&sprefix=cereal+bo,aps,163&sr=8-43&th=1

https://www.amazon.com/Desiccant-Indicating-Dehumidifier-Electronic-Documents/dp/B0DRFFLMZB/ref=sr_1_11?crid=O0E1A8BJCP2O&dib=eyJ2IjoiMSJ9.daoRy45bYtcce3OT2mmqMYUJ3X7IbKsjDBt25jzQC2RDTrTb5CjTc-GbgCxizad8A7KdyufGNpvZtiwKNPkxAvo4ZmKAPcmYcTBYtKoIfxl_z62U14Rnw5aALVQOh882RbqQYVLQ55DYVZlTfS-RMURrf3w7ku8WjhvTfnknM62y4ht8Rj3s0K-LvPBsE8FLM-5rA2t7gsnGUNzUtSK49aYg5RWIwp76ByVtQIEqww8.LAg_4zNx2RfEe1NH81MrdTlUckYagU31_zWjqjMPpjs&dib_tag=se&keywords=blue+desiccant+bag&qid=1756917941&sprefix=blue+desicant+bag,aps,163&sr=8-11&th=1

https://www.amazon.com/Hygrometer-Humidity-Thermometer-Fahrenheit-Thermostat/dp/B0CXHS6CYS/ref=sr_1_6?crid=GASGCJ463BND&dib=eyJ2IjoiMSJ9.AddNxuw9aT8KWwUF3gUI5cbSD9LMZTDhBj6eOlAVqNGzSVbbtv33s6apySsBmJWBJmUFxhT1i3mPH6qaVSkNQBlVwxw8lKke1i6NG8IsYX-lBfng0L4yfeFRkJ1TPMXpk-mBKr75MAsI_ZUjMtaSWWAP7gGijLYMTOE1mSs2Os_72RZukgoDW7VofJH4WzIjBMPvEq20B7kphxFMWpq_Uqp9eGMH6cOJ95A8MFouRVGSdUuS2Pqpf5aI7ONhz8bnD0TPcZC2AzGBRMDMH4C-n5Cops4bzV3VFeS75hLah0s.IYlRBatXjNRT_vhU7I8TUOf_YtpDWKfBPDUbio_yVtI&dib_tag=se&keywords=humidity+sensor&qid=1756918546&sprefix=humidity+sensor,aps,197&sr=8-6

View attachment 41901

marcytech

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 463

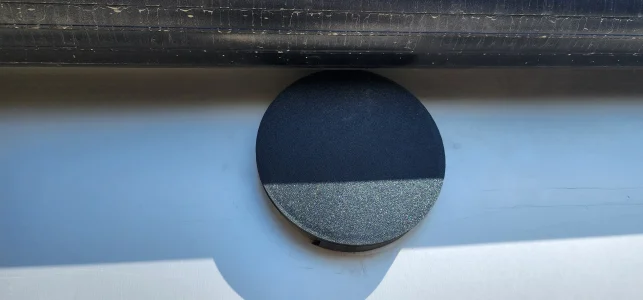

I’ve been using petg cf on a few test pieces and I really like the cf surface finish. It prints pretty easily if you have a big part but the smaller parts tend to lift so a little glue helps.

I just picked up some Asa cf to try out since it’s more uv and heat resistant with properties similar to abs.

Abs is probably my favorite to print but I don’t like the look of the exterior walls so I’m hoping I can get the asa cf to work well

Here’s the petg cf surface

I just picked up some Asa cf to try out since it’s more uv and heat resistant with properties similar to abs.

Abs is probably my favorite to print but I don’t like the look of the exterior walls so I’m hoping I can get the asa cf to work well

Here’s the petg cf surface

Attachments

Asa cf is really nice. I like printing with it. I just got a spool of PC FR that I am planing to play with, supposedly its pretty next level.I’ve been using petg cf on a few test pieces and I really like the cf surface finish. It prints pretty easily if you have a big part but the smaller parts tend to lift so a little glue helps.

I just picked up some Asa cf to try out since it’s more uv and heat resistant with properties similar to abs.

Abs is probably my favorite to print but I don’t like the look of the exterior walls so I’m hoping I can get the asa cf to work well

Here’s the petg cf surface

This is a little ABS project I did, basically its a sun shade for my trailer speakers when its parked at my house. There is a base that goes uper the speaker then the cover slides on.

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

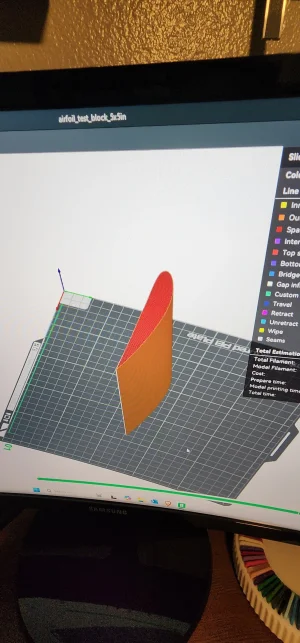

Inspired by the AI model thread I took a photo from fiberwerx website, cleaned it up a bit with Gemini, and used Rodin to create a 3d model that I scaled and printed for an SCX24. It got remarkably close for me doing no real work. They have a multi photo option that would help get it closer but it's a paid subscription.

UR_Mawm69

Well-known member

ok ok ok............

what the fuck

where/when/how/who wtf started this 3D print thing????

i feel like everyone and their mother does it and has one now.

how much is like a base model printer? how big are they?

do you just buy a block of material and put it in the "machine"?, load your 3D SW/cad/whatever file, and push go?

really starting to wonder about this stuff.

what the fuck

where/when/how/who wtf started this 3D print thing????

i feel like everyone and their mother does it and has one now.

how much is like a base model printer? how big are they?

do you just buy a block of material and put it in the "machine"?, load your 3D SW/cad/whatever file, and push go?

really starting to wonder about this stuff.

marcytech

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 463

Wait, what!?Inspired by the AI model thread I took a photo from fiberwerx website, cleaned it up a bit with Gemini, and used Rodin to create a 3d model that I scaled and printed for an SCX24. It got remarkably close for me doing no real work. They have a multi photo option that would help get it closer but it's a paid subscription.

View attachment 42521

Motiracer38

Well-known member

- Joined

- Apr 27, 2022

- Messages

- 499

Bronco is all finished up. Asked Rodin the AI politely to model a bronco based off a Fiberwerx picture, scaled to fit on Cura slicer, designed the TTB chassis, and put it all together so that I realize I don't know how to build TTB steering and my son could break it repeatedly. Fun little project though.