Endless Trails

Well-known member

- Joined

- Apr 7, 2022

- Messages

- 575

Coming home from the only real complaint I had was with my bed setup. So I am doing another bed reorganization. Mainly flipping my drawer and fridge to opposit sides of the truck. But there are other ideas I want to incorporate at the same time.

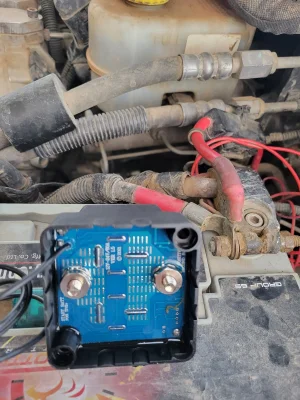

I wanted to also move my house batteries from in the bed to below the bed but I couldn't figure out a way to do it the A) wouldn't hang to low. B) wouldn't require major fab in cutting the bed floor and/or frame crossmembers. C) wouldn't be in the way of the third member or exhaust. So for now they are staying in the existing battery box located in the drivers side front of the bed. I haven't decided if I am going to relocate the OBA and ARB compressors yet.

I wanted to also move my house batteries from in the bed to below the bed but I couldn't figure out a way to do it the A) wouldn't hang to low. B) wouldn't require major fab in cutting the bed floor and/or frame crossmembers. C) wouldn't be in the way of the third member or exhaust. So for now they are staying in the existing battery box located in the drivers side front of the bed. I haven't decided if I am going to relocate the OBA and ARB compressors yet.