triple_fcked

Active member

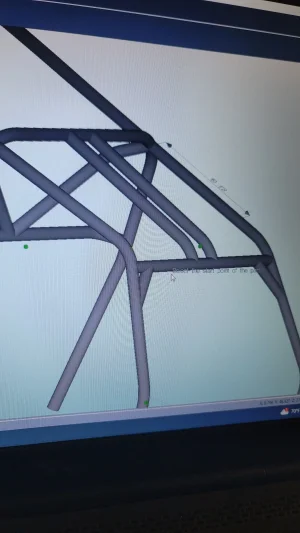

I figured I would start a thread to document the build so far. I didn’t start the build but I would say I’ve gotten it extremely dialed in from when I first got it.

Specs:

1994 Toyota 4Runner 22RE

RUF Springs Front, Chevy 63” Springs rear

Front Axle: +5 Rock Assault, 6 Shooters 30 spline OG Longfields, IFS hubs with tacoma brakes, 5.29 w/Detroit Locker

Rear Axle: IFS width; 5.29 w/ Grizzly Locker

Fox 2.0x12” RR Shocks

Locked 2.0x2.0” Front Air bumps

5 Speed, Dual cases 2.28x4.7

Bought this beauty off facebook marketplace in November of ‘22.

Bought this beauty off facebook marketplace in November of ‘22.

I was putting around in an 80 series land cruiser but I caught the bug for The Hammers after a trip down there when I had to keep parking the land cruiser to ride along on “real trails”

My brother helped me drive it 9 hours from Northern California sight unseen. I was trailing with my daily filled with all of our spare parts and tools, but we actually had zero issues the whole way.

I didn’t know how to drive stick yet, so we parked it at a buddy’s property in Lucerne valley and I went back up there the next weekend to wheel it and learn how to work the stick, then had a trial by fire driving it home.

Specs:

1994 Toyota 4Runner 22RE

RUF Springs Front, Chevy 63” Springs rear

Front Axle: +5 Rock Assault, 6 Shooters 30 spline OG Longfields, IFS hubs with tacoma brakes, 5.29 w/Detroit Locker

Rear Axle: IFS width; 5.29 w/ Grizzly Locker

Fox 2.0x12” RR Shocks

Locked 2.0x2.0” Front Air bumps

5 Speed, Dual cases 2.28x4.7

Bought this beauty off facebook marketplace in November of ‘22.

Bought this beauty off facebook marketplace in November of ‘22.I was putting around in an 80 series land cruiser but I caught the bug for The Hammers after a trip down there when I had to keep parking the land cruiser to ride along on “real trails”

My brother helped me drive it 9 hours from Northern California sight unseen. I was trailing with my daily filled with all of our spare parts and tools, but we actually had zero issues the whole way.

I didn’t know how to drive stick yet, so we parked it at a buddy’s property in Lucerne valley and I went back up there the next weekend to wheel it and learn how to work the stick, then had a trial by fire driving it home.

Last edited: