You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Learned a new 3d printer trick

- Thread starter 2012SVTSC

- Start date

marcytech

Well-known member

- Joined

- Apr 6, 2022

- Messages

- 414

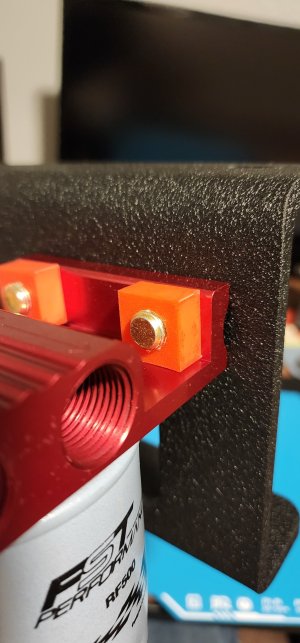

Good idea!My fav “tool” to make with my printer is drill guides. Here’s an example of a drill guide I made for a vent hole with .375” radius in each corner.

I also printed the honey comb mesh while I was at it.

Turboyota

Well-known member

- Joined

- Apr 1, 2022

- Messages

- 810

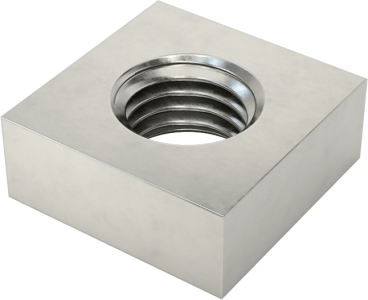

I press drill bushings into 3d printed trim & drill jigs all the time for work. Most jigs last a few cycles, unless the drill bushings heat up from improper drill angle, clogged chips, or a really deep hole that causes heat buildup in the drill bit.

For high temp lamination molds I’ve used Ultem For 250f+ cure cycles for carbon fiber/epoxy prepreg. I’ve made dissolvable mandrels for complicated bifurcated ducts and all kinds of cool shit I can’t show pictures of.

I’ve even made quickie changes to wind tunnel models leveraging 3D printed bits. There was a fuckload of filler, primer, and hand sanding, but fuck, it’s a fast solution in a pinch.

Also made some 3D printed D44 knuckles to proof a billet concept…

For high temp lamination molds I’ve used Ultem For 250f+ cure cycles for carbon fiber/epoxy prepreg. I’ve made dissolvable mandrels for complicated bifurcated ducts and all kinds of cool shit I can’t show pictures of.

I’ve even made quickie changes to wind tunnel models leveraging 3D printed bits. There was a fuckload of filler, primer, and hand sanding, but fuck, it’s a fast solution in a pinch.

Also made some 3D printed D44 knuckles to proof a billet concept…

Last edited:

Dzrt_ranger

Member

- Joined

- Oct 1, 2022

- Messages

- 32

Have definitely been contemplating a 3D printer! They’re not that pricey either.

the bodj

Well-known member

There's a couple of companies that make these tube contour gauges for $50-60 (not including laser). I'm cheap, so I drew my own up in fusion and will be using 3/32 tig filler rod. Rubber band keeps tension on the rods, and the insert holds a $15 shotgun laser bore sight, so I can aim at the other end of the tube junction. The fits are pretty good right off the print bed, but I want to dial them in a bit more. Once I get all of the fits just right I may sell them as a kit for $25-30 with laser included. I may be able to get it down to $25 shipped.

the bodj

Well-known member

Anyway you can make me one of those with a closed end and a girthier, I mean larger ID. Maybe in light pink..?

Open end is easier to wash out. Rookie

96f-u250

Active member

- Joined

- Apr 4, 2022

- Messages

- 222

I like to bottom out.Open end is easier to wash out. Rookie

dwphoto

Administrator

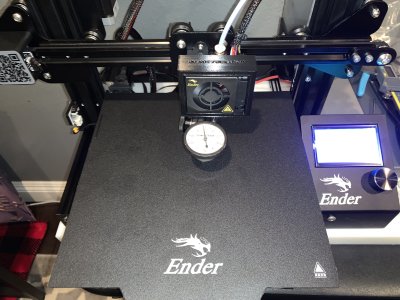

Santa picked up a 3D printer for my son. (Ender 3)

Spent some time putting printer together yesterday. Haven't even turned it on yet.

Was wondering what software you guys running for your 3d printers.

Spent some time putting printer together yesterday. Haven't even turned it on yet.

Was wondering what software you guys running for your 3d printers.

RandyG

Active member

Best advice with an Ender 3 is to watch a ton of videos on YouTube. This was my first printer and there is definitely a ton of tinkering that had to happen to make it work well. Get good at tramming the bed and setting your Z height.Santa picked up a 3D printer for my son. (Ender 3)

Spent some time putting printer together yesterday. Haven't even turned it on yet.

Was wondering what software you guys running for your 3d printers.

I started with the paper trick, then moved to feeler gauges, then eventually printed up a dial indicator mount for the head. Made leveling/tramming super easy.

I used Cura for my slicer. I use Onshape/fusion for CAD. Typical websites for finding files are thingiverse, printables, cults3d, maker world.

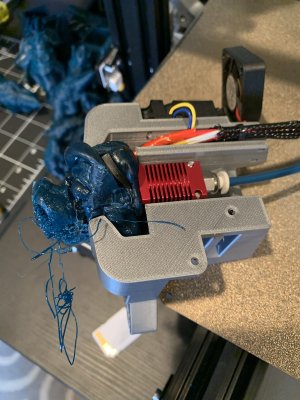

If you really get into it, Ender 3’s are highly modifiable. It will for sure teach you and your son the ins and outs of printing. I tore mine down so many times trying to figure out why it wasn’t working and to upgrade it. Don’t get discouraged with it, it really is a fun hobby that you can use for a ton of different things.

I still have my Ender 3, though it doesn’t get used. I put so much time into it that I couldn’t get rid of it when I upgraded printers. The only parts that are stock on it is probably the frame

Also for some safety: the power wires going into the board are probably tinned with solder. This can be a fire hazard with loose connections due to them heat cycling. Idk if that’s been fixed from the factory, but I recommend cutting the ends and crimping on some ferrules to go into the posts.

Attachments

For a slicer I only use bambulab studio, because it's set up for retards like me, works awesome with minimal effort. They have ender presets and filament presets that are great starting points.Santa picked up a 3D printer for my son. (Ender 3)

Spent some time putting printer together yesterday. Haven't even turned it on yet.

Was wondering what software you guys running for your 3d printers.

dwphoto

Administrator

Best advice with an Ender 3 is to watch a ton of videos on YouTube. This was my first printer and there is definitely a ton of tinkering that had to happen to make it work well. Get good at tramming the bed and setting your Z height.

I started with the paper trick, then moved to feeler gauges, then eventually printed up a dial indicator mount for the head. Made leveling/tramming super easy.

I used Cura for my slicer. I use Onshape/fusion for CAD. Typical websites for finding files are thingiverse, printables, cults3d, maker world.

If you really get into it, Ender 3’s are highly modifiable. It will for sure teach you and your son the ins and outs of printing. I tore mine down so many times trying to figure out why it wasn’t working and to upgrade it. Don’t get discouraged with it, it really is a fun hobby that you can use for a ton of different things.

I still have my Ender 3, though it doesn’t get used. I put so much time into it that I couldn’t get rid of it when I upgraded printers. The only parts that are stock on it is probably the frame

Also for some safety: the power wires going into the board are probably tinned with solder. This can be a fire hazard with loose connections due to them heat cycling. Idk if that’s been fixed from the factory, but I recommend cutting the ends and crimping on some ferrules to go into the posts.

Thanks for the info! I'm sure I'll have some stupid questions for you guys.

I've been trolling YouTube a little bit. The instructions were trash to put the thing together haha YouTube to the rescue. Started watching a leveling video this am didn't get very far with the kids battling with each other. Might have to save that task when it quiet haha.

Stoked to go down the rabbit hole on this... have no clue what I'm doing haha.

E

dwphoto

Administrator

oh I'm in good company then... 100% mouth breather here.For a slicer I only use bambulab studio, because it's set up for retards like me, works awesome with minimal effort. They have ender presets and filament presets that are great starting points.

RandyG

Active member

Thanks for the info! I'm sure I'll have some stupid questions for you guys.

I've been trolling YouTube a little bit. The instructions were trash to put the thing together haha YouTube to the rescue. Started watching a leveling video this am didn't get very far with the kids battling with each other. Might have to save that task when it quiet haha.

Stoked to go down the rabbit hole on this... have no clue what I'm doing haha.

E

Definitely when it’s quiet

3D printing has a solid place in the shop and on the truck. I’ve made a ton of parts to fix stuff around the house, in the garage, on the truck. I even 3d printed some dies for my tubing bender to bend up some 1” DOM for side mirrors.

I think there should be a 3d printing sub forum, as they are getting way more accessible. I love seeing everyone’s prints

Similar threads

- Replies

- 7

- Views

- 443